BBT News

Do you also have the feeling there are only coming more wars in the world?

Seems like war is no solution because rarely ends.

Local people always are the real victims.

Our VW buses, don’t they conduct enough messages of peace?

Political leaders should be driven in VW buses, they should not make war.

To make the buses dependable they can always call us.

Our aim is (and always will be) to bring better parts to give old Volkswagens eternity.

Welcome to the BBT News.

We extend our bus bumper line from our SWT program.

We already carried the front bumper 66-67 “Diamond cut” HERE

Now we add the rear diamond cut bumper plus both slash cut bumpers.

BBT SWT bumpers come in L82 Silver White color, exactly like original.

0012-601 Bumper front – Bus 09/58-07/65 (Euro) Silver White SWT

0013-601 Bumper rear – Bus 09/58-07/65 (Euro) – Silver White SWT

0013-602 Bumper rear – Bus 08/65-07/67 (Euro) – Silver White SWT

Running out of used always motivates our search for replacement.

Engine lid springs no different.

Our “used” boxes showed empty bottoms so the search was on.

Today we add both missing engine lid springs for your Beetle.

Our complete Beetle & Bus line of engine lid springs HERE

BBT # 2303-110 can be used for Karman Ghia front and rear hood too.

Although original Ghia’s have a slightly larger diameter springwire so are little stronger.

This might result your Ghia hoods do not stay open that firm as intended.

2303-110 Engine lid spring – Beetle 05/55-07/64

2303-120 Engine lid spring – Beetle 08/64-07/67

As a wash out of our emergency brake handle line development we made our own dowel pin for the emergency brake cable hook up.

This dowel pin fits buses from 1960 all the way up to 1971.

Resulting in better prices and nicer quantities.

Emergency brake handles for your splitty bus HERE

Other emergency brake handle hardware for Split or Bay HERE

0523-020 Dowel pin for emergency brake cable – Bus 06/60-07/71

0141 Front hood 1300 68- with grill

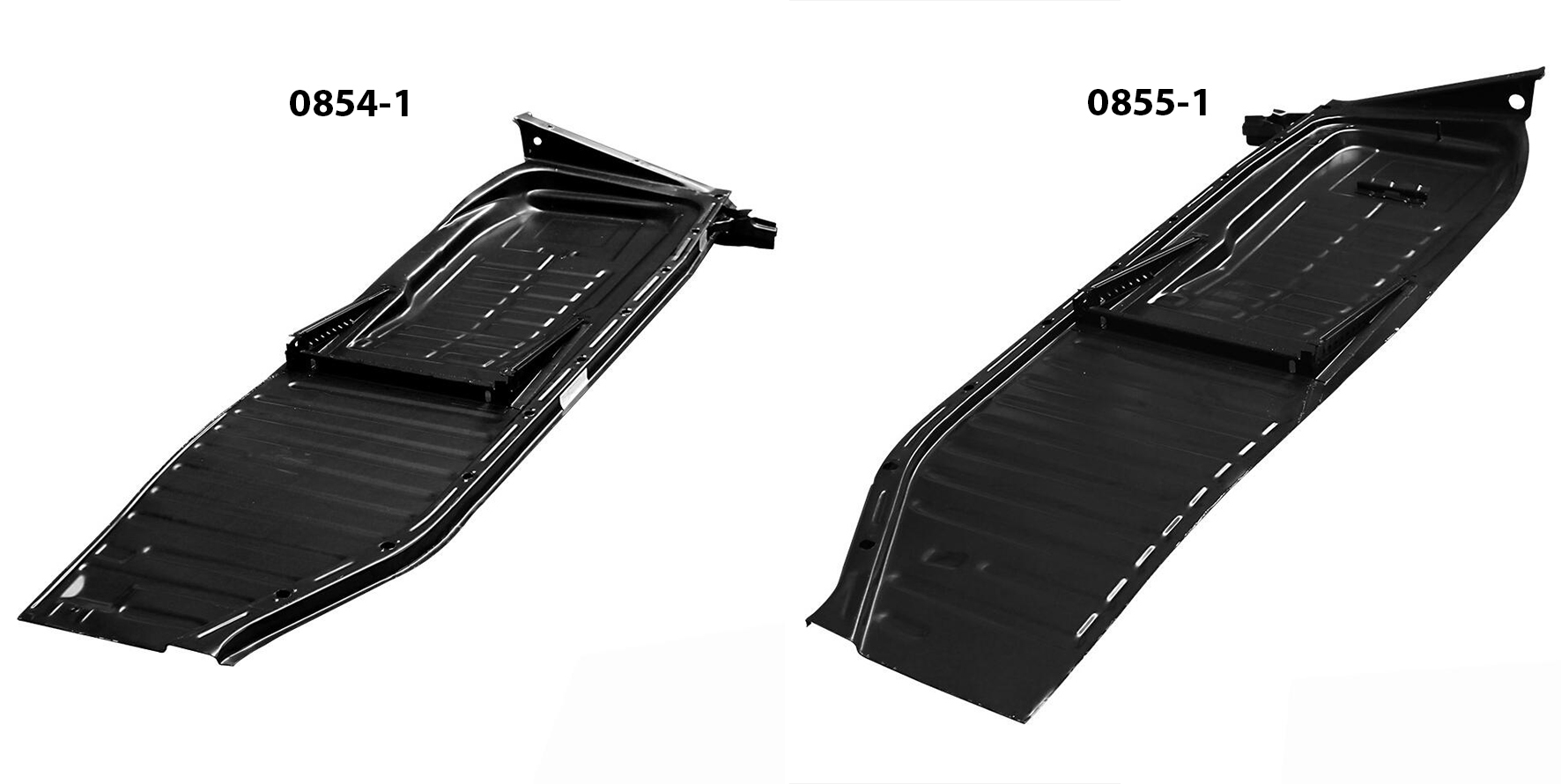

0854-1 Floor panel left (0.75mm) – Beetle 08/70-07/72

0855-1 Floor panel right (0.75mm) – Beetle 08/70-07/72

0854-3 Floor plate left (0.75mm) – Beetle 08/72-

0855-3 Floor plate right (0.75mm) – Beetle 08/72-

BBT News team wishes you a peaceful weekend.

BBT News

This week we had the big earthquake in Taiwan.

BBT has plenty connections there and supplies from this beautiful country.

Especially the rural east Coast was hit hard, thanksGod the area with the lowest population.

Also, in capital Taipei and other cities there was damage.

But all the factories we work with seem to be ok and people are alive and kicking.

Nature is and stays unpredictable.

Classic Volkswagens do not have that kind a secret anymore for us.

Every week we’re just adding new products.

This week we let the sunshine in, if she comes out that is.

Welcome to the BBT News.

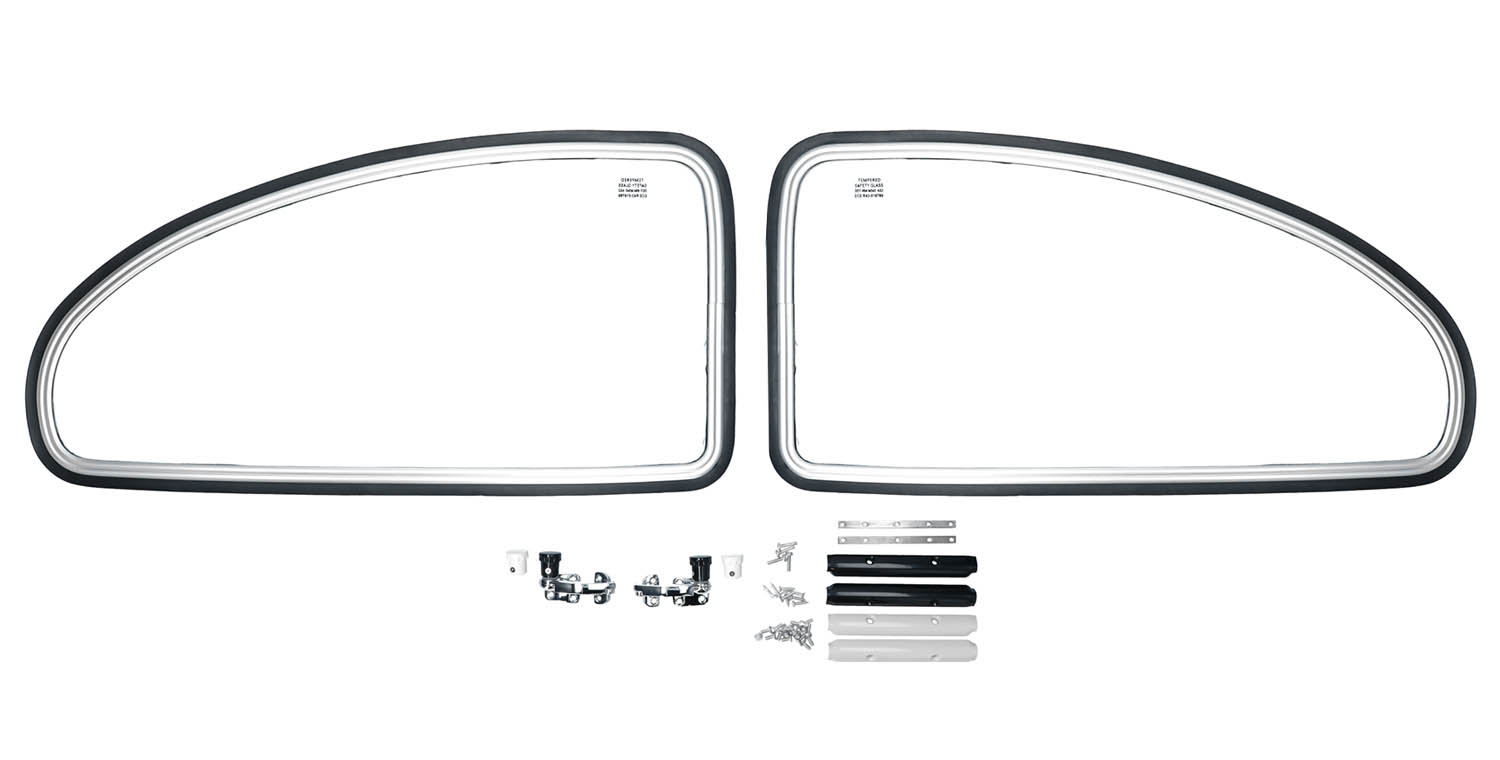

Spring is here, open your windows…

BBT adds low-cost Safari windows for your bus.

Front and rear opening windows for fresh air and cool looks.

Besides front we add for small window in small tailgate up to 1963,

and for wide window for 64 to 79 tailgates.

That is right, also for Bay window!

Deluxe large window for small tailgate -63 will follow later on this year.

We use polished high grade stainless steel for these safari window kits.

Polished stainless steel means small scratches or dull corners can be easy corrected by extra polishing.

All our Safari window kits come complete with all necessary hardware for easy mounting.

For these new kits we especially worked on price.

Our top-of-the-line Safari window kits HERE now leave you the choice in quality.

Stay cool this summer with BBT safari window kits for every budget.

0396-100 Safari windows front (kit) – Bus -07/67 RVS polished – ECO

0396-500 Safari window rear (kit) – Bus 03/55-07/63 RVS polished – ECO

0396-520 Safari window rear (kit) – Bus 08/63-07/79 RVS polished – ECO

More safari with these small rubbers.

These small rubbers go between your safari window catch and the safari window frame.

Original used on early frames, nice add on for all year’s frames.

VW never published on their exploded views.

We had to find them in the text of the (early) parts books, what we did…

Thanks to BBT Stephan a new useful part for our beloved safari window kits.

Sold each.

0397-012 Rubber Safari window lock – Bus -07/67

Do you know BBT sells also the correct phenolic washers to mount between your wing nut and metal sliders?

They are the only type wing nut washers that really work for your Safari windows.

Exactly like original, sold each.

0397-015 Safari wingnut washer, phenolic – Bus -07/67

0664-200 Headlightgrills Speedster style – Beetle/Bus -07/67, Porsche 356 (pair)

Porsche 914 is and stays part of our Volkswagen heritage.

Back available out of popular demand.

Only for four cylinder 914 Volkswagen Porsches.

Six bangers need their specific manual.

9349 Haynes manuel VW Porsche 914 /4

BBT NEWS team wishes you a cool spring weekend with lots of safari open window fun.

BBT News

Easter is for Christian people the start of the new life.

For many Volkswagen people the start of an exciting new season.

Many times, to finish and show off their new projects.

For BBT we feel the community awakens again.

….. like a new life….

Happy Easter everybody, enjoy the start of something “new.”

BBT is closed on Easter Monday being a Belgian public holiday.

Welcome to the BBT News.

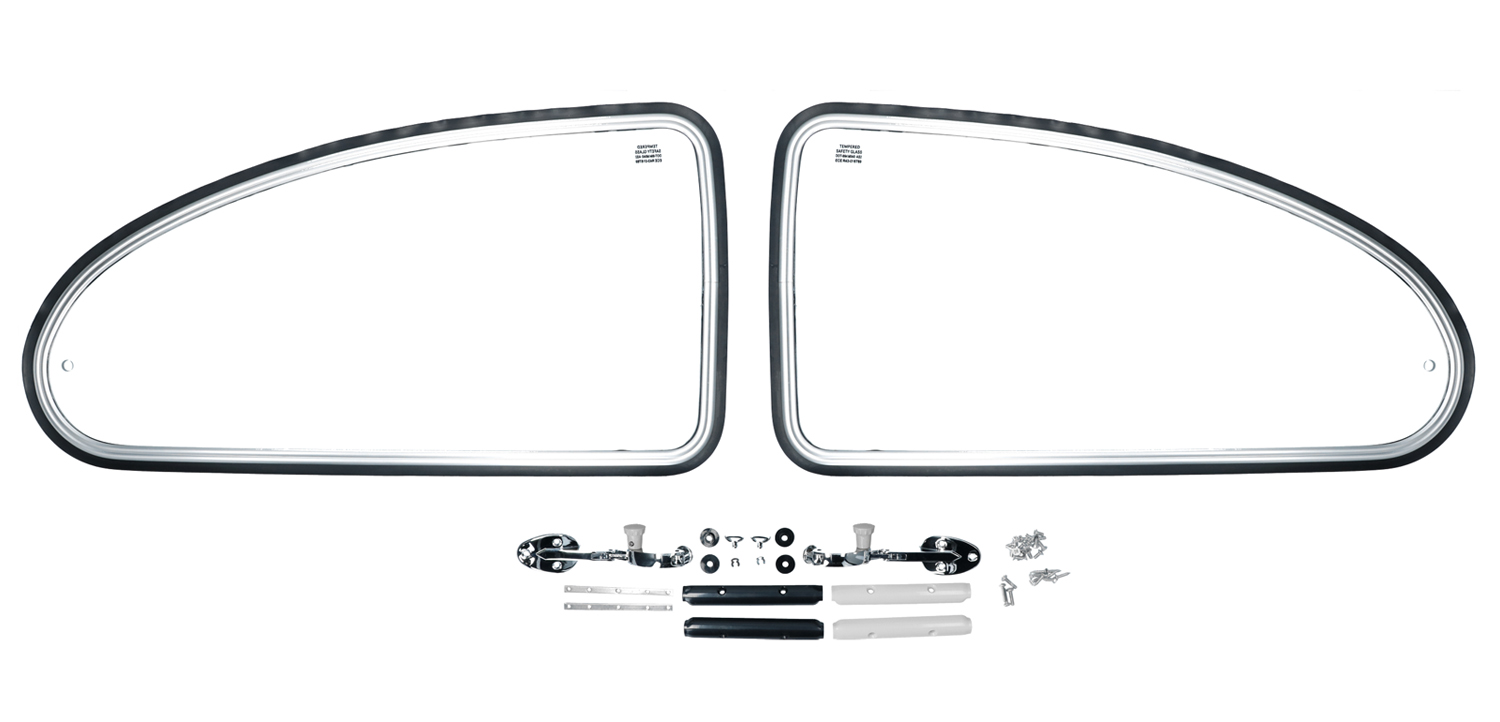

BBT introduces pop out windows for early and late model Beetle.

We bring you the best on the market today.

BBT pop out kits come complete and contain all you need for a perfect installation.

Glass is sitting in an anodized aluminium frame that holds the rubber.

Hinges come with two assorted colors covers.

Pop out locks and all necessary hardware included as well.

Perfect add for any Beetle.

T1 lovers this one is for you!

BBT already carried multicolor door-check straps for the high hinge cargo doors.

They have a length of 175mm.

High hinge cargo doors go to the end of production year 1960.

Also for all years Brazilian made split window Kombi.

Too long for low hinge cargo doors who require a length of 143mm.

We introduce today the same multi-colors for low hinge doors.

Used on German made buses from 1960 up to end of production.

Also, for the rear door on all split and Bay window Double cab pick-up trucks.

Sold each.

Our entire family door check straps HERE

0438-619 Door check strap cargo door blue – Bus 12/60-07/67, double cab 12/60-07/79

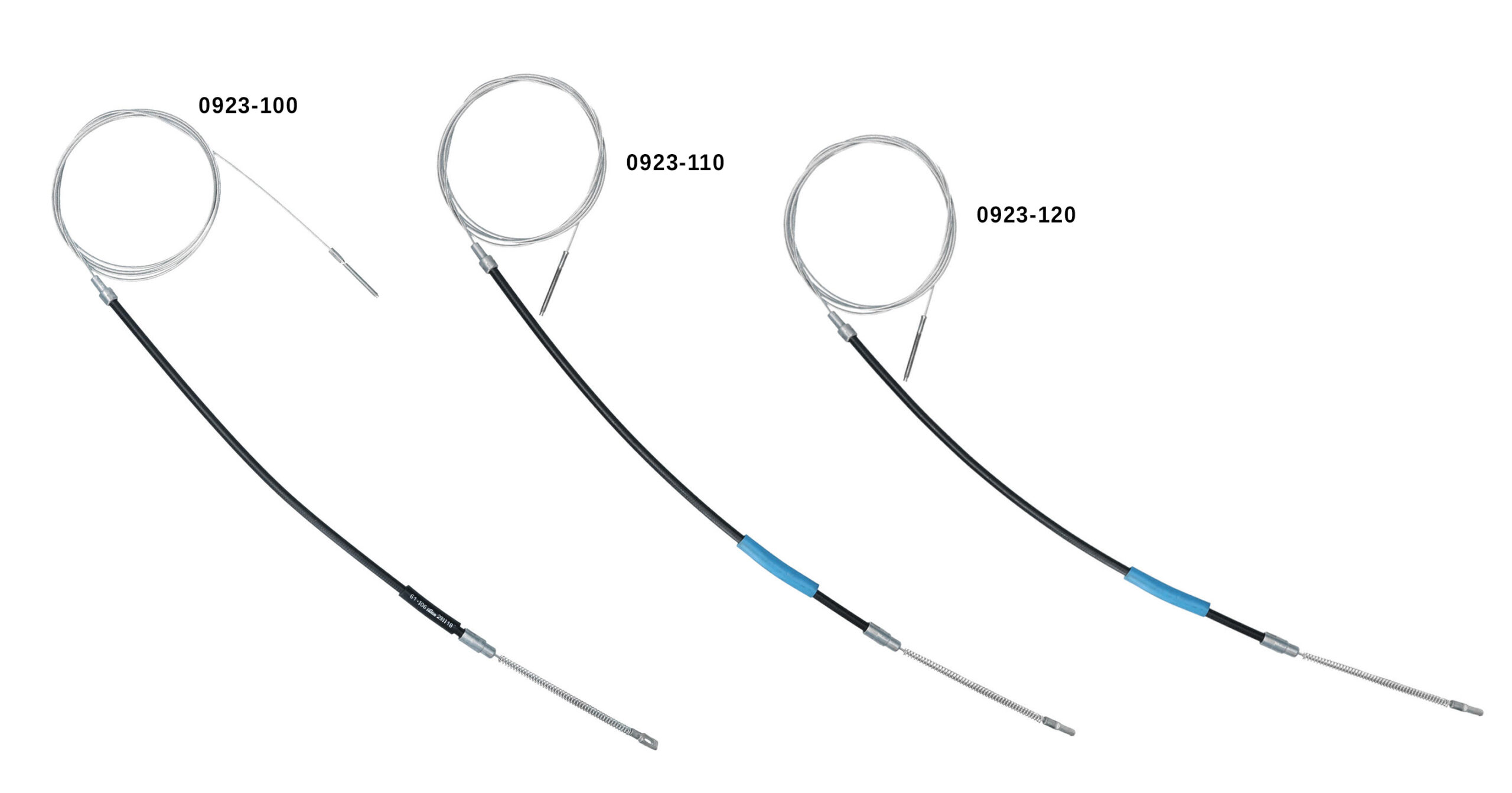

In our aim to serve all air-cooled Volkswagens we also expand our parts line for Brazilian made Kombi’s.

Brazilian Kombi use different emergency brake cables than their German made counterparts.

We expanded our product line with emergency brake cables also for Brazilian made Kombi.

All correct length cables available now.

All other emergency brake cables we carry HERE

0923-100 Handbrake cable – Bus Brasil -01/78

0923-110 Handbrake cable – Bus Brasil 02/78-04/82

0923-120 Handbrake cable – Bus Brasil 05/82-95

BBT News

Next week it will be Easter.

Easter boosts always a spring feeling.

New life, new nature, new car season!

Is your ride ready for the season?

Let us help you with our new products….

…. for this week…. as every week.

Welcome to the BBT News.

The next two clutch discs are a direct replacement for your stock clutch discs.

Solid center means no central torsion springs to leave.

The center of the discs made from spring steel gives a little torsion, but from there you get full grip.

The lay out of the woven material is made for a stronger connection between flywheel and clutch mechanism.

The Heavy-Duty model is perfect for heavy loads or light competition.

BBT Bob tested this clutch disc in his 1959 SO 23 Westfalia on a 5000 km road trip through the Balkan in the summer of 2023.

The disc didn’t miss a grip, the whole trip.

While Bob is not exactly the driver to stay on the beaten path……

The “Kush Lock” disc is rather for competition from mild to wild.

Each clutch disc comes in 200mm diameter.

Our regular SACHS 200mm clutch disc HERE

1501-100 Clutch disc 200mm Heavy Duty

1501-120 Clutch disc 200mm Heavy Duty ‘Kush Lock’

We add the cupholder with USB charger for the bay window bus!

All T2’s can charge their phones now!

Easy installation, you just span in your ashtray, no drilling, no screws.

Tested by BBT Arjan for strength, position, and durability!

Well-designed with a feature to hold your phone!

Your phones always charged for navigation, playlists or even to stream movies!

Don’t watch movies while driving!!

You can also check BBT News of course.

A cool one within reach for driver and passenger.

Are you ready for the road?

Our other USB charger devices HERE

0699-265 USB charger, cup/phone holder for ashtray 12Volt – Bus 08/67-07/79

BBT chooses “Filter King” for their fuel pressure regulator set ups.

Need better mileage? But a fuel pressure regulator doesn’t only do that.

Fuel pressure regulators give a correct pressure of your gas entering your carburetor(s).

That is much more important as one could think.

We tested many and the only one that really works is “Filter King”.

We now add the fitting for 6mm fuel lines.

We make our “Filter King” fuel pressure set ups available for more applications.

Our entire “Filter King” line of products HERE

1689-224 Fuel line fitting 6mm ‘Filter King’

BBT wishes you a splash in the spring weekend.

Finish that car and take it for a ride!

BBT News

Globalisation was something magic.

Was, unfortunately no longer.

Still, we can travel quite a bit.

Visiting factories, discussing productions.

This helps us tremendously bringing you new or better-quality parts.

As every week we show you our latest releases.

Welcome to the BBT News

Let that fresh air come in on those hot days.

Give your Beetle that uber cool stylish look parked at any show.

BBT Safari window kits are a real head turner.

Besides our Bus safari windows HERE we now stock also safari kits for 58-64 beetle.

BBT stocks a lot of custom accessories to let your pride stands out.

Our safari kits come with all necessary hardware.

0394-100 Safari window front (kit) – Beetle 08/57-07/64

After Germany we can honestly state Brazil is the second Volkswagen country in the world.

Brazil features the largest Volkswagen factory outside of Germany as well.

Although sharing a lot of parts with their European colleagues there are quiet some specific parts to Brazilian built Volkswagens.

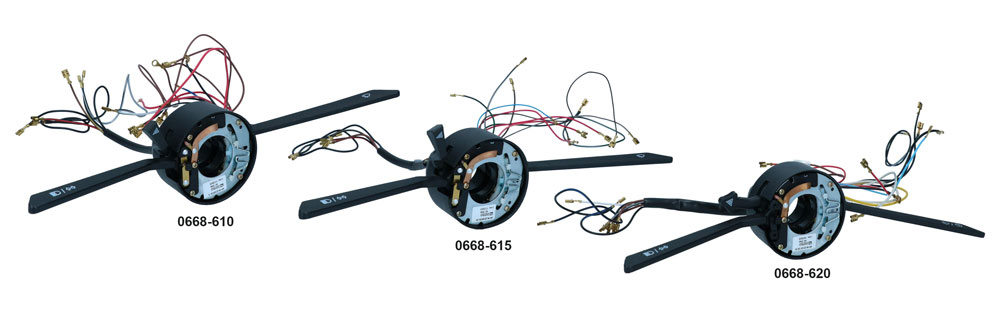

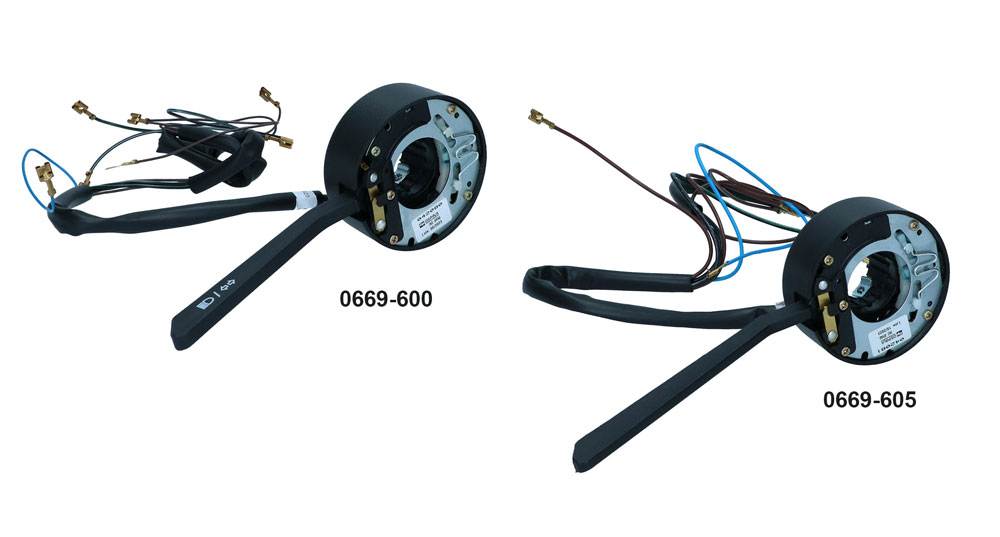

The indicator switch is one of the unique features on Brazilian beetles and buses.

With the mass import from Brazilian Volkswagens into Europe lately and demand after specific spare parts, we decided to stock all model indicator switches.

Especially for these family members from far away.

If you have a Fusca (beetle) or a Kombi Clipper or Carat from Brazilian Heritage, chances are big we have the exact and correct indicator switch for you.

The differences are small sometimes, but we decided to stock the whole range, because your Brazilian beauty deserves nothing less.

0668-600 Indicator switch – Beetle Fusca -76

0668-605 Indicator / wiper switch – Beetle Fusca 76

0668-610 Indicator/ wiper switch – Beetle Fusca 78-81

0668-615 Indicator / wiper switch – Beetle Fusca 82-92

0668-620 Indicator/ wiper switch – Beetle Fusca 93-96 ‘Itamar’

0669-600 Indicator switch – Bus Brazil 75-76

0669-605 Indicator switch – Bus Brazil 76-81

0669-610 Indicator / wiper switch – Bus Brazil 81-89

0669-615 Indicator / wiper switch – Bus Brazil 90-94

0669-620 Indicator / wiper switch – Bus Brazil 95-2014

BBT News Team wishes you a wonderful weekend!