We’re working on a quality label for our BBT brake hoses and will give you the sample here of what will appear at every brake hose in every catalog, digital or printed in the future…

BBT Brake hose, commitment to quality, safety and quality test program.

The BBT Brake hose is made in a factory that’s really world class.

One of the only brake hose factories in the world that produces literally everything in house, nothing else, only brake hoses or parts thereof.

Numbers don’t lie, in this case up to two million brake hose connectors (the metal piece on each end of the brake hose) a month and up to 8000 Brake hoses (in 4 production lines) per shift, if necessary they could work in a continuous three shift workday…..

This is serious business from a serious manufacturer with necessary certifications to supply OE (assembly lines of car manufacturers) but also aftermarket.

For the air-cooled Volkswagen market BBT is the exclusive customer.

So what can we assure as quality?

We followed for you the complete test program ourselves and are happy to share this with you here, and on every single brake hose we sell from now on.

Our brake hose production is monitored by 4 different quality tests along the way…

Test 1. Pulling test

Here they really put weight on both end of the brake hose to see how far they can pull it until it snaps.

Automotive standard is stretch up to 158kgs according current SAE norms.

We witnessed they surpassed this numbers big time and the connector blew off only at over 351 kgs, what’s the double of the national standard to us.

Frequency of the pull test is at least once every shift for every production line.

Frequency of the pull test is at least once every shift for every production line.

Test 2. Explosion test

When you pull the brake pedal You put pressure on your brake hose through your brake fluid.

The maximum operational pressure You will ever achieve is 80kgs in a car and never ever over 120kgs in trucks.

We witnessed in this test pressure of over 500kgs on the hose for full two minutes, and from there moved up to over 900 kgs, without the brake hose exploded.

The test was stopped here for security reasons… 900kgs of pressure is a LOT!

The frequency of this ‘’explosion’’ test is at least daily. Every single batches of brake hose undergo this test.

The frequency of this ‘’explosion’’ test is at least daily. Every single batches of brake hose undergo this test.

Test 3. Volumetric expansion test

The volumetric expansion test validates the brake hose for its expansion using pressure.

That is, the hose cannot expand more than that was established by the SAEJ1401 Standard enabling that the braking system obtains the planned result.

In “normal human language” this test checks if the hose keeps the same flow and don’t bulge or push hose canal wider open under high pressure to ensure the brake fluid flow stays the same in volume in all conditions.

This will give you a steady brake pedal the moment you press with your foot…

If you like to get numbers… The specification for the expansion test is that it is less than 0.68 cm³/m by 6.9Mpa; less than 0.79cm³/m by 10.3Mpa.

This test is carried out weekly. A sample is taken individually from each braiding machine, to ensure that the textile reinforcement is meeting quality standards.

This test is carried out weekly. A sample is taken individually from each braiding machine, to ensure that the textile reinforcement is meeting quality standards.

Test 4. The Ozon aging test

This test creates an environment in the machine for the brake hose according to the parameters previously established.

According to SAEJ1401, the amount of ozone in the environment must be 100PPM, humidity of 70%, temperature of 40 ° C over a period of 70 hours.

To pass, after 70 hours of uninterrupted testing, the brake hose cannot have cracks in the rubber.

This test is relatively new in the program and is in operation since beginning of 2020. We do this test because there was some small problems with the outer rubber layer about two years ago. We work continuously on a better product.

The Ozone aging test is performed monthly, to ensure a quality outer rubber layer mainly, but also to test the rubber and textile layers on the inside.

The Ozone aging test is performed monthly, to ensure a quality outer rubber layer mainly, but also to test the rubber and textile layers on the inside.

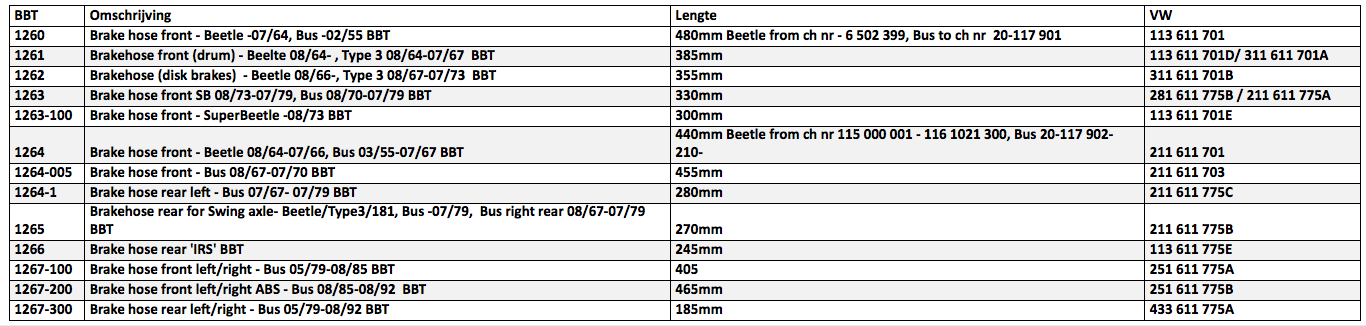

BBT is selling over 10.000 Brake hose every year to all corners of the world. We stock following models.

Other models can be made to measure if You concern certain quantities.

Normal service recommendation for brake hose requires a general check of brake fluid and brake hose condition every service interval. Brake fluid change is generally recommended every 2 years, or at least seriously testing. However, this is a generic recommendation, each brake fluid manufacturer has its own specification within the DOT standards and is informed to the consumer in their respective packaging.

Our brake hoses are fully guaranteed for 3 years, but even if older we would appreciate to get them back for research to make a better product.

This commitment to quality is the least we can warrant our customers for their brake parts.

Buy the BBT brake hose because we care for your quality, we talk brake parts after all!

All further information on Info@BBT4vw.com