We visited some serious injection factories who make all kind of neat stuff for all and new cars, for OE (assembly lines) as for aftermarket… and now they understand they have a third market, the Classic car market…

Very interesting products been discussed and development of other products has been evaluated… good things to come….)

Unbelievable we need this kind of big machines to make parts for our beetles and buses, always wonder how they did it in 1951?

A mix of pictures from several factories we visited….

We always like our manufacturers employe happy people, and that was for sure her, they all waved to us!

These girls assemble small parts, whole day long…. for us, to put on our Volkswagens!

We saw big injection machines, these machines You need to make all kind of plastic, for an example the side protection plates for 73-76 beetle seats….:)

We saw even bigger injection machines, these are for large parts, currently this machine don’t make parts for us yet…

This is the inside of an injection machine, man can only wonder what such a tooling cost…:)

Something completely else… a pneumatic assembly machine for door switches, one model only, 6000pcs a day…. crazy!

What we’re cooking today Jerry?

An eagle view from an injection machine set up… three machines, one operator….

We visited several lab’s, quality control, material evaluation, production quality etc etc… this one was really impressive, as it was really ultra clean!

Something else again…:) very well organised factory make electrical components mainly, this visit was a blast!

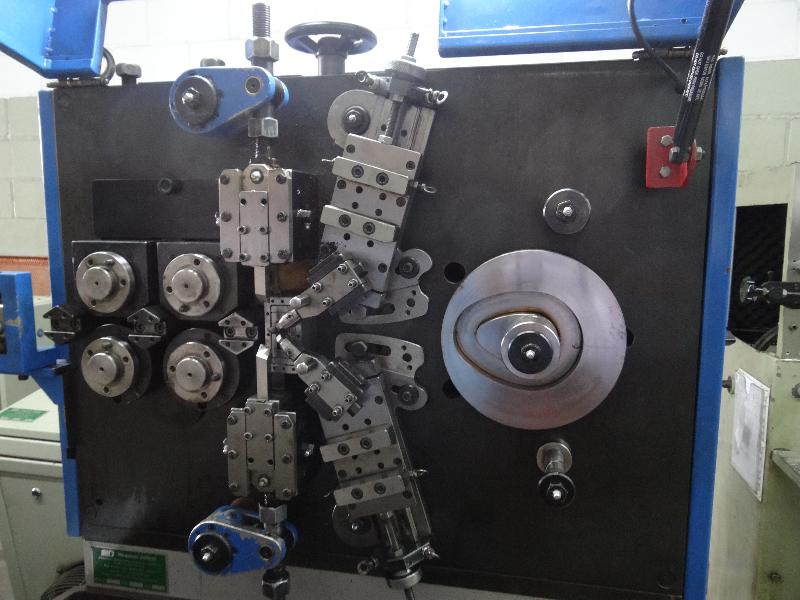

Springs, who need springs? this is a fully CNC operated Spring making machines, all kind of springs….:)

We saw raw material in tons and tons, good factories protect themselves in Brazil with inventory, because the market tendencies are way more volatile as for an example in Europa its necessary to think ahead and has a huge inventory, what start with raw material off course, here for 6 months.

Off course it’s also a guarantee for your workers they have at least six more months work!

This a part of a tooling department from one of our suppliers. The days that Brasil had only dirty small factories hardly under a roof are over.

Brasil now a days is a modern economy with lots of modern factories…

If You like tooling, well check them out here… as Jerry did…:)

These tooling make a lot of Volkswagen parts …..

Oh inventory is real necessary as said before, also from finished product!

This is IGP, one of our suppliers for fenders, floorplates etc… the factory is on both sides of the streets…:)

We we’re kind a late so we didn’t make a factory tour, only had a boring meeting regarding some quality issues, but, we came out with a cool new plan… stay tuned for updates…:)

Tha way back to the city; Sao Paolo skyline or part there off… crazy city, crazy people, crazy business, we just love it….

Happy we’re working again on better parts, and help out problems for the entire VW community…

we continue our travel report on saturday as tomorrow (friday) we have the weekly BBT NEWS with all new arrivals for the week… so a lot o come…:)