BBT never sleeps, always on the run for better and perfection…. working on a better (VW) world.

We brought you the front fenders for the early beetles. Off course this was a learning experience. There was some small trial and error.

With our last production we gave our fenders 8 small updates and although many people would mention a few, hardly nobody will mention all…

Therefor we take our time to explain (and show) the last production changes.

Beetle Front Fender Improvements

1. Adding the Drain Hole

For both Split Window and Oval Window fenders.

Diameter of the drain hole measures 5mm with no lip.

Location shown with picture below, fender edge to hole edge 85mm.

2. Captive Nut under headlight bucket for split window models.

For the Split Window (49-52), we switched to MGT captive nut, measure 20 x 14mm.

For the Oval Window (53-59), no change was needed., square nut is kept.

3. Fender bottom recess.

The recess measures 52mm.

This applies to both Split Window and Oval Window fenders.

We made sure it’s a nice curved corner as original and not the square corner as it was before…

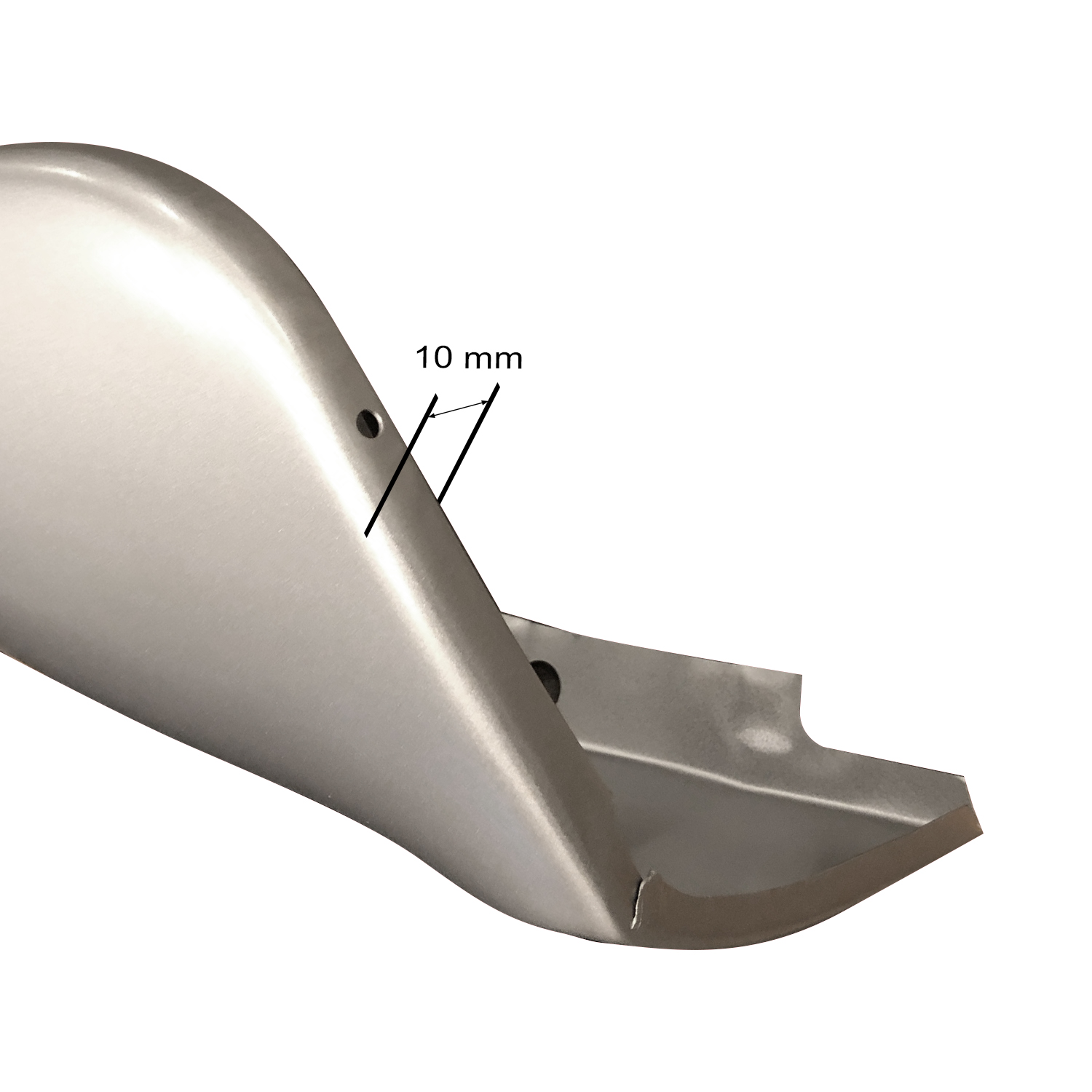

4. Fender bottom lip is now even.

This lip needs to have the width of 10mm end-to-end.

5. Horn Grille holes can have only the 4 tab slits on RHS split window fender!!

Just the holes of the 4 tabs. We no longer cut the entire grille round hole

Only on RHS Split window fender (49-52)

LHS fender keep having the complete horn grill cut out hole.

Oval window fenders (53-59) keep there two oval cut out holes.

6. Horn Grille Orientation

We changed the lay out of the horngrill tap holes from our split window fenders (53-59).

The lines of the horn grill are now square to the lower side of the fender bolt line…

Both dimensions A are now the same.

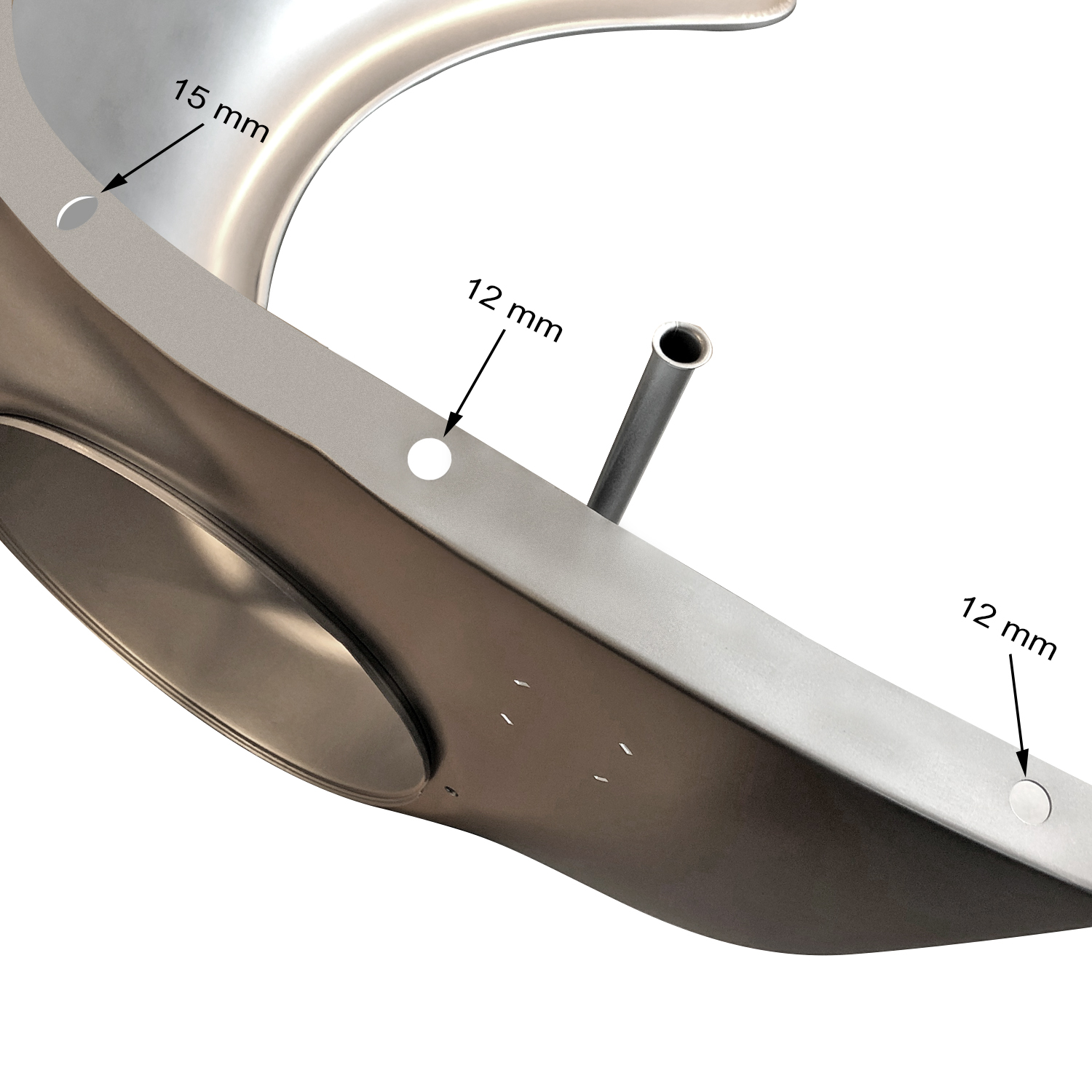

7. The 2 first fixing holes from front are now 12mm diameter , all others 15 mm.

This is for both Oval and split window fender.

We assume the front holes been made 12mm only in the factory as reference holes. On the assembly line they first put in front fender bolts in the reference holes. This way all other holes lined up more easy.

Anyway this was a feature we found on all studied original fenders and therefor brought this to our production models…. mandatory…

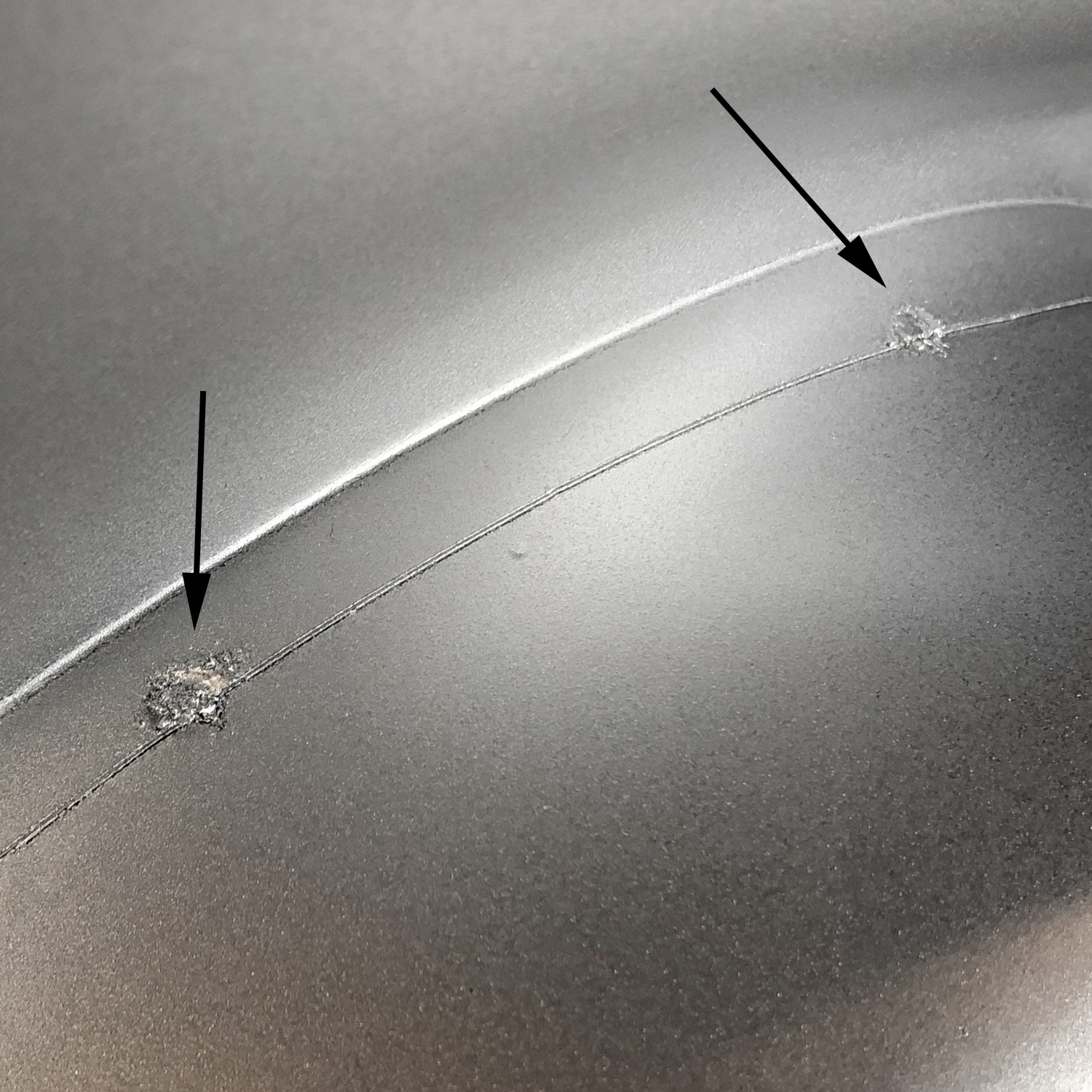

8.The fixation of the headlight bucket.

While not completely like original we made a lot of progress welding the headlight bucket into the fender.

We use another way of welding, what’s closer to the original as it was before.

Eight upgrades to make a better and more accurate product.

We like to thank all people for sending their feedback from all over the world.

There is still floating a lot of fenders from our first production all over the globe for now….

Because details matters….

5 Comments

Leave a CommentHi, How about the pressing in between the bolt holes in the flange? I believe they were ment for grease..Are the new fenders available for 48? Without holes for horn grill?

Nice

Hi Lars

Front fenders never had the pressing between the bolt holes, only rear fenders had this, our rear fenders being tooled up for right now will have these as well. but front fenders don’t….

Fenders seems to change in 1949, although its only visual, they should come a little deeper…. but if You don’t have originals, I think our fenders are perfect for a 1948, and yes we have standard versions without horn grills.

always at your service

Bob

Awesome job and great focus on details. Your fenders might even be better than originals. So nice to see a company that cares about their products.

Thank You for your comment Carl

Altough we do our best as good as we can, our fenders are not better as original, although we do come very close.

But we have to face the facts that there is a big difference between the production of a 1000 fenders or 100.000 fenders as the factory did… completely different world

But we will keep producing and try to make a better product along the way, where never statisfied, quality is an endless job…

Stay tuned for updates

Bob