More factories, more parts, more machines and….more friendly people, we’re in Brazil after all!

Rubber mixing, the preparation of the rubber for the extrusion machines…. hard work!

This is the inside of a rubber extrusion machine and mould…:)

Extrusion machines are not exactly small! Pretty impressive right?

Hard working factory employees finishing our products as it should… Multo obrigado guys, Thank You very much!

More extruders, this place had plenty!

And yes, we like to check on inventory, in a country as Brazil it tells a lot about the financial situation of the company…:)

Up to the next, smaller, supplier. But here the aim on quality and service is extremely high! We just love these guys!

As You can see they’re extremely well organised….

Happy workers, means many times good quality jobs!

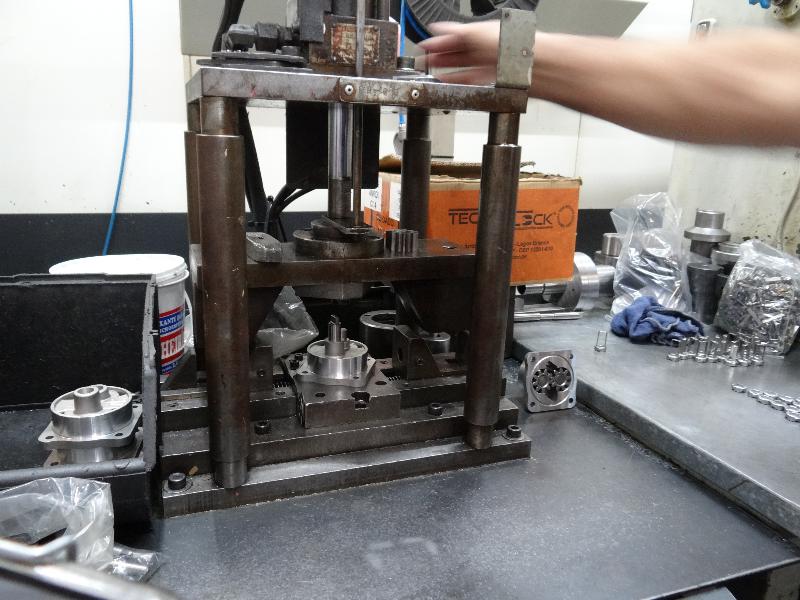

Let’s learn about oil pumps, and find out to start-up production for 25/36 Hp correct oil pumps….

This IS Mr Oilpump himself! Assembling oil pumps for over 35 years, any questions? Plse ask!

Cup grinding of oilpump covers, for a perfect finnish!

Hardworking people, finishing oil pumps….

This is an aluminum extrusion machine…. you really should feel the heat! Astronomical!

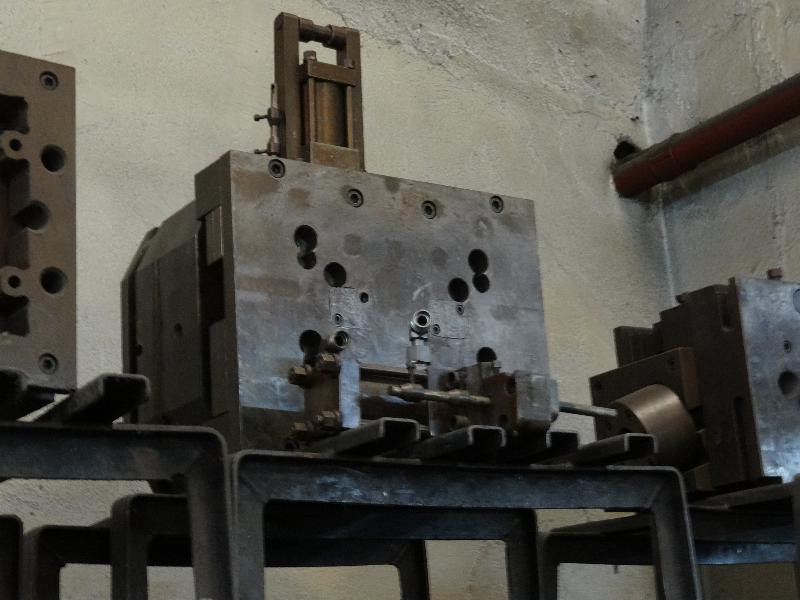

This tooling extrudes around 7000 oil pump housings a year for aircooled Volkswagens. There’s two tooling for the base… together they “pump” around 12.000 units yearly… all to keep our aircooled friends on the roads!

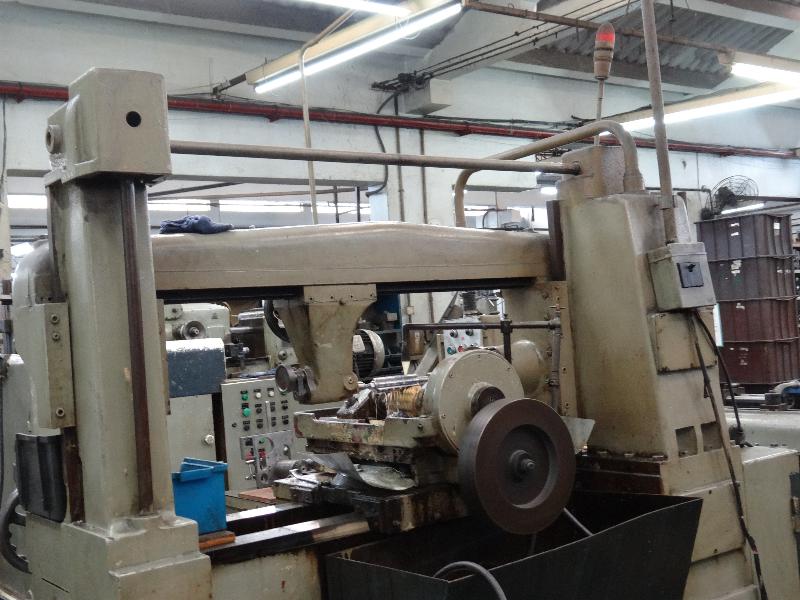

This machine grinds the gears for the oil pumps, very specific job!

In another (small) factory we discussed a production of early vent wings, but quality was not there yet, let’s see what the future brings… there was other interesting projects going on here too, more later…:)

Next stop was a factory that is specialised in small parts casting, alu and zinc extrusion and fuel pumps….

We will try to bring back all model fuel pumps in their original looks, not just as a replacement spare part, but as a full value restoration part. Details are important for our cars, especially in the engine bay!

You like soup? Hot aluminum around 700°C!

He guys don’t look so serious, its only VW parts!

Time to drive back to the hotel, back to the city…

Lots of driving, we spends many hours in the car… And too many visits, but we learn a lot and meet many of our suppliers, can discuss many many products, quality, delivery times etc… is it worth it? You bet, somethings You can only do in a personal contact, it simply don’t work by phone or email….

First week is over, another week to go! So stay tuned!