We visit the foundry where they cast all tooling… this has to happen somewhere…:)

Shin, Niels and Andy are all ready for it, safety first!

Here the styrofoam is coated and placed in to big steel cages. They fill up the cage with sand and closed to poor liquid metal in.

The styrofoam melts away, and the perfect form of the part stay inside the moulds.

The perfect start to mill out the perfect tooling for the part.

Remember there’s always three tooling necessary; Male, female and overhead. so three castings necessary for every tooling!

The grey parts below are coated styrofoam models…

In close up they look like this…. this is coated styrofoam… ready to go in the cages…

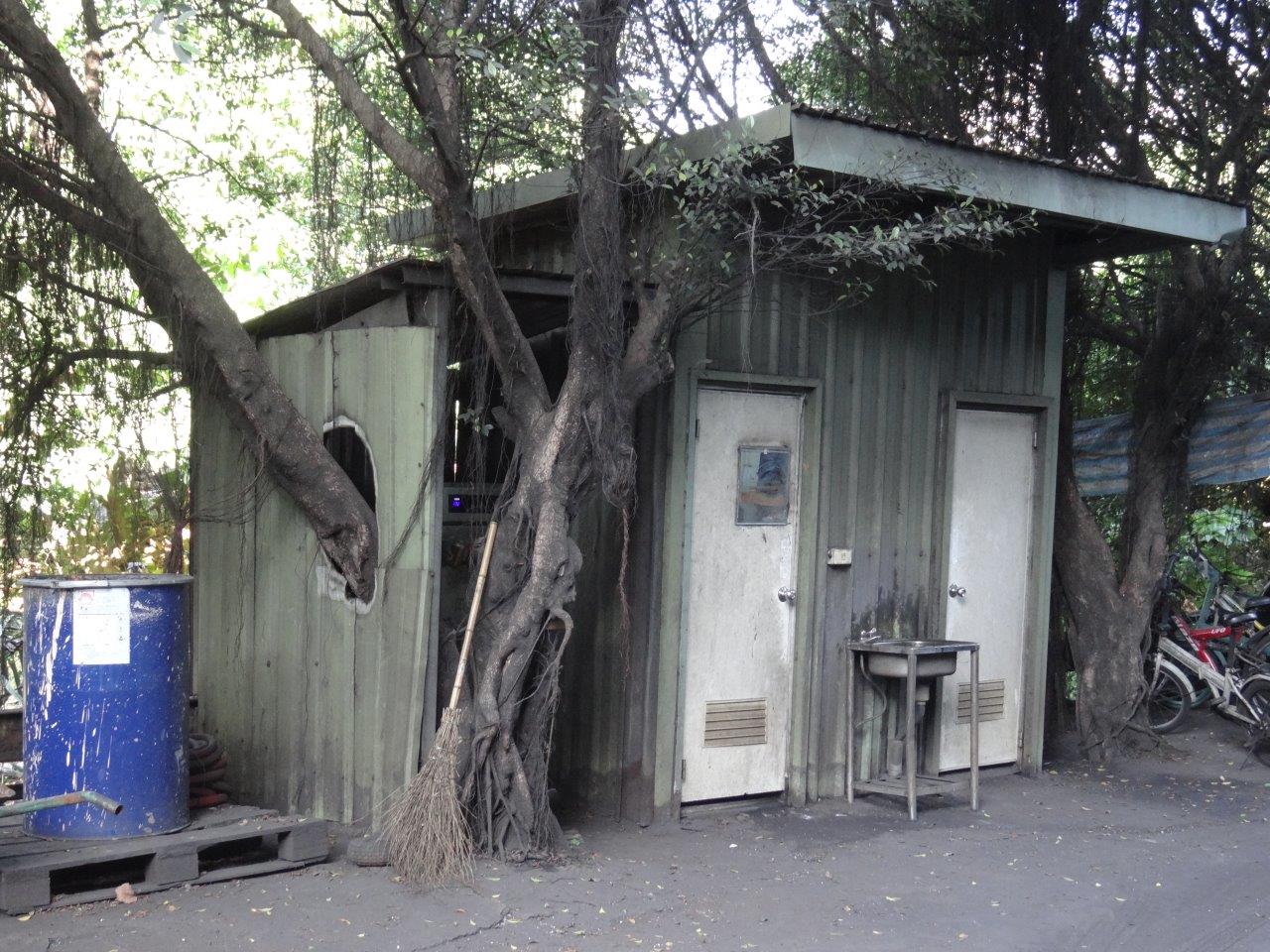

The trees growing here literally out of the restroom….:)

After casting and cleaning, some small parts might be necessary for adjustment, this happens by welding… this is how freshly cast steel moulds do look….

This is an iron pouring bucket. The pouring of liquid metal happens at night only to save on energy costs… sorry we didn’t gave up our sleep to capture that…:)

How they fill the cages up with sand, the styrofoam is already inside…

The tooling are huge as you can compare dimensions with the workers on top of it, these are regular man, no dwarfs…:)

The breaking of the sand from the metal once it comes out of the cages… a pretty dusty work…

Don’t we all like the industrial views of factories brave enough to make our parts? You bet!

We continu our factory visit report tomorrow so stay tuned!!